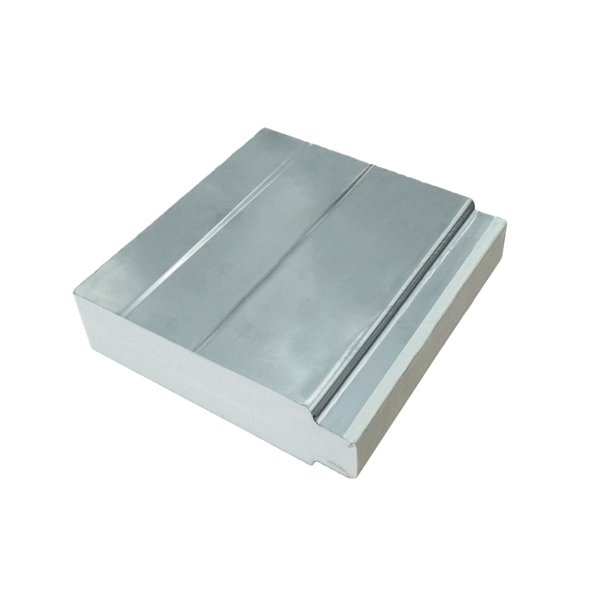

Description of Cold Room Panels

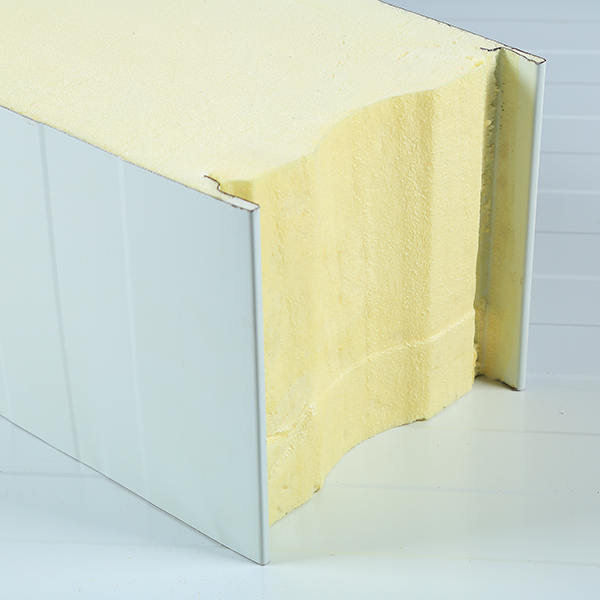

The panels feature a pressed-in compression rib or a smooth surface, with color coated steel plates ranging from 0.4 mm to 0.8 mm in thickness. With a width of 1m, our cold storage panels provide effective insulation using polyurethane (PU) as the core material. They have achieved a fire rating of B1 and B2.

These panels are lightweight, structurally simple, and boast a visually appealing appearance. They effectively address temperature differences in the cold storage industry, making polyurethane foam insulation panels the ideal choice for cold stores, rooms, and warehouses.

Advantages of Polyurethane Insulated Panels for Cold Storage:

Enhanced insulation and air tightness design.

Exceptional load-bearing capacity with zero deformation.

Significantly reduced construction time by over 40%.

|

Product Parameters

|

|

The thickness of steel plate

|

0.4-0.8 mm

|

|

The thickness of core material

|

30-200 mm

|

|

The density of core material

|

40 kg/m³

|

|

Effective width

|

1000 mm

|

|

Length

|

< 11.8 m for transportation

|

|

Thermal conductivity (W/m.k)

|

≤ 0.023

|

|

Colors

|

Customization (Any RAL color)

|

|

Fire rating

|

B1, B2

|

Applications

Our cold room panels are ideal for a wide range of applications, including preserving the freshness of food, freezing milk and meat, and storing items requiring specific temperature conditions. As a result, they find extensive use in hotels, restaurants, pharmaceuticals, agricultural facilities, chemical industries, and any other setting that requires reliable cold storage solutions.

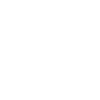

About Us

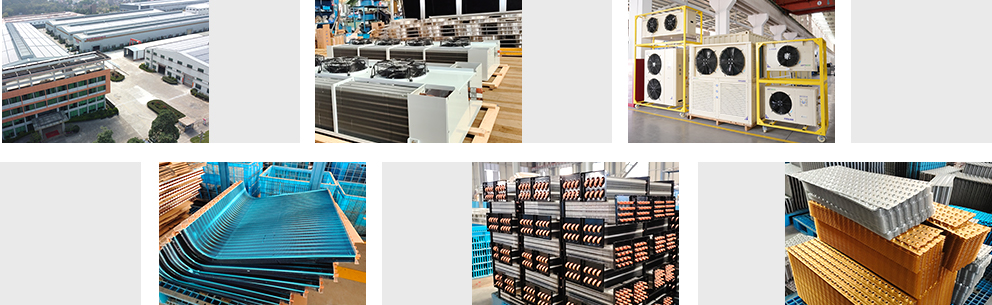

Reliable Manufacturer of Commercial Refrigeration Equipment

We are a professional refrigeration equipment manufacturer with a 150,000 sqm modern factory in China. With advanced production lines and an experienced R&D team, we specialize in producing a wide range of cold storage solutions and commercial refrigeration systems. Our main products include condensing units, air coolers, cold room panels, cold storage doors, and refrigeration compressors. We support OEM & ODM services to meet the diverse needs of global B2B customers.

Exhibitions

Connect with Us at Industry Trade Shows

We regularly attend both domestic and international refrigeration exhibitions to stay up to date with industry trends and connect with global clients. We also support our agents and partners to participate in local expos. Welcome to meet us at upcoming trade fairs!

Why Choose Us?

30+ Years of Manufacturing Expertise

With over 30 years of experience in refrigeration equipment manufacturing, we’re more than just a supplier—we are a strategic partner to help you scale your business. Our factory and engineering team are dedicated to delivering reliable, energy-efficient products that meet commercial and industrial demands.

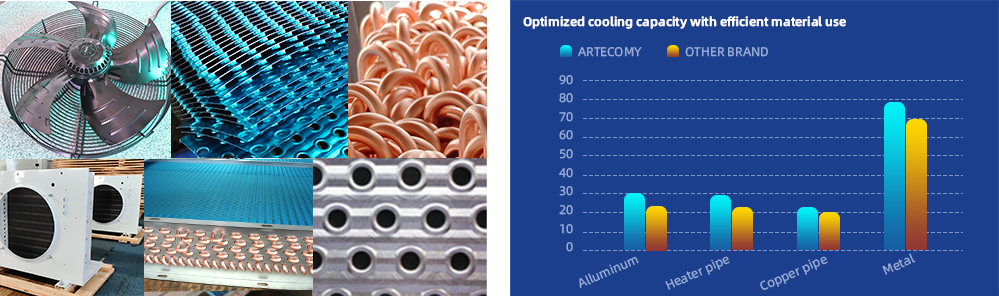

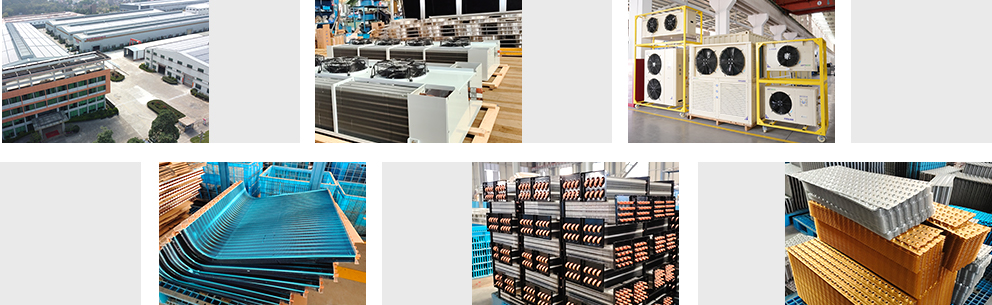

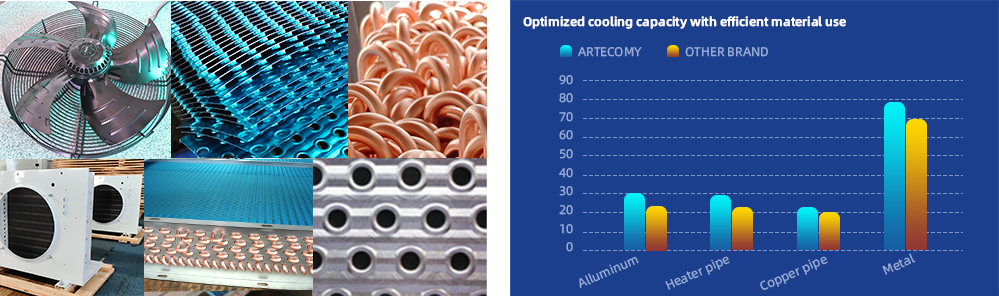

High-Quality Materials for Better Performance

We use only top-grade materials to ensure long-lasting and stable performance:Aluminum fins and copper tubes for efficient heat exchange;Heater pipes and water collection plates for better defrost;Solid structure and optimized internal design for energy savings;While many suppliers cut corners, we believe in delivering value and quality to every order.

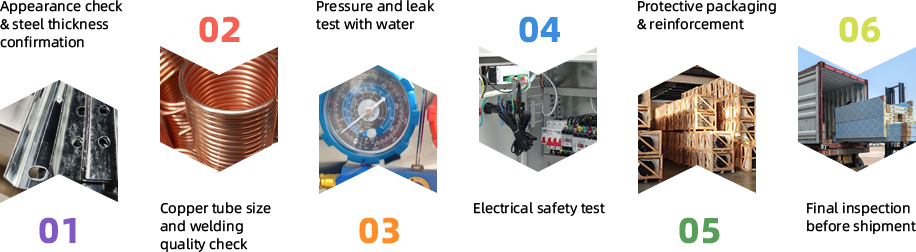

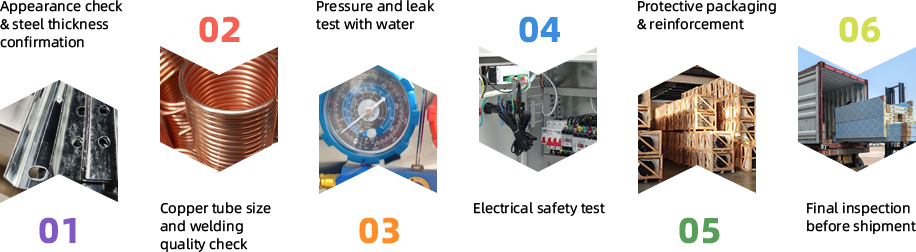

100% Quality Control Process

6-Step Quality Control: Every Product inspected Before Delivery

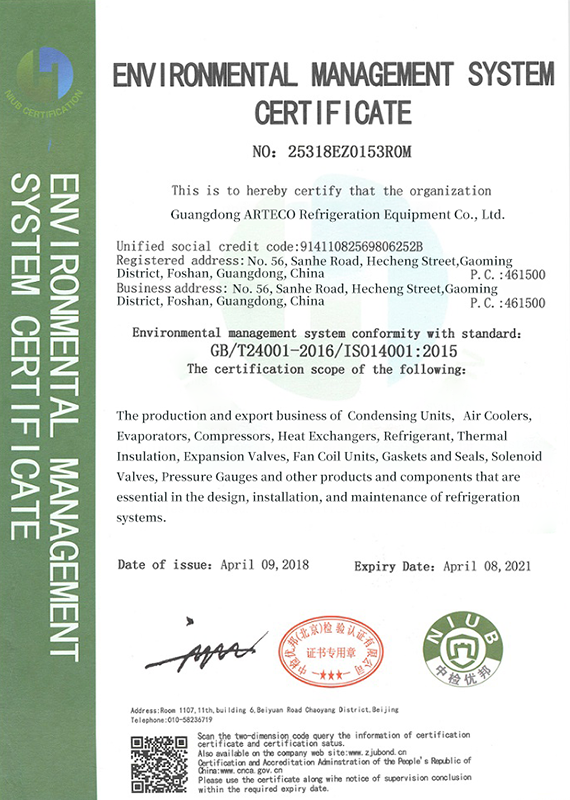

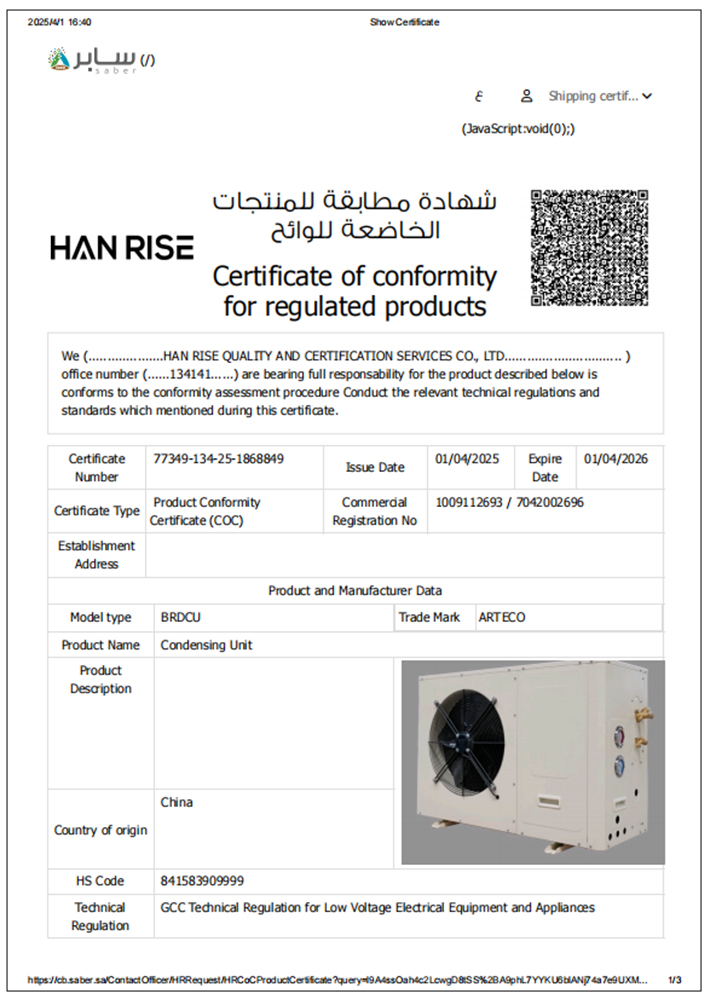

Certified Reliability

Certified Quality You Can Trust

Frequently Asked Questions

Everything You Need to Know Before You Order

1. Are you a factory or trading company?

We are a direct factory located in Foshan, China. With a modern facility and skilled team, we specialize in manufacturing refrigeration equipment. We welcome you to visit us anytime. OEM/ODM services are available for global clients.

2. Can I get a sample?

Yes, samples are available. However, the cost and shipping will be at your expense.

3. Can you produce based on our design or drawing?

Absolutely. We can manufacture based on your samples, drawings, or technical specifications.

4. Can I use my own logo or branding?

Yes, we support OEM & ODM. Your logo and design can be applied to the product and packaging.

5. How do you usually pack the goods?

We use bulk packaging or sturdy wooden boxes suitable for container shipping. Customized packaging is also available upon request.

6. What is your delivery time?

In-stock items: 3–5 days after payment

Custom orders: Usually 30–40 days

We’ll confirm the delivery schedule before order confirmation.

7. What are your payment terms?

30% deposit in advance, 70% balance before shipment

Payment methods accepted: T/T, Credit Card, PayPal, Western Union, Cash

8. What delivery terms do you support?

We support various terms including FOB, CIF, CFR, EXW, etc. We will help you choose the most economical and efficient method for your order.

9. Can you help with project design or cold room layout?

Yes. Our team can provide technical support, layout design, and product recommendations based on your project needs.

10. Do you offer after-sales service and technical support?

Yes. We provide online support, video instructions, and spare parts service to ensure smooth installation and operation.

11. Can you support large volume or urgent orders?

Yes. With a large production capacity and flexible scheduling, we can meet urgent or high-volume demand for B2B projects.

12. What industries are your products suitable for?

Our products are widely used in food cold storage, pharmaceuticals, logistics, supermarkets, and industrial refrigeration systems.

13. How do you ensure product quality?

We have a strict quality control process, including appearance check, leak test, electrical safety test, and final inspection before shipment. All products are ISO9001 and CE certified.

marketing@brdecogroup.com

marketing@brdecogroup.com +86 13318205907

+86 13318205907 EN

EN EN

EN CN

CN FR

FR